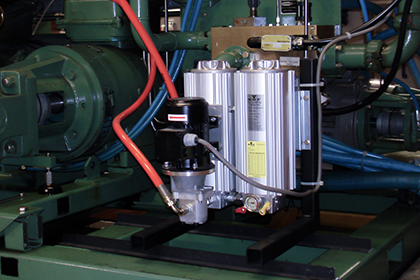

Filter & Purify

Throughout the day, the heating and cooling of operating temperatures and the environment can have an effect on your oil. The extreme changes cause the breakdown of additives and creation of contamination within the equipment. Filtering the oil using either dedicated or portable solutions ensures the removal of contamination, keeping your equipment running longer and more effectively.

Continue the Journey

Filter Oil to Optimum ISO Cleanliness

Using the correct lubricants and ensuring they are in suitable chemical condition is a prerequisite for success, but the big changes in component service life are achieved by the aggressive management of lubricant contamination. In most cases, the amount of particle contamination in the oil is the largest single factor that determines how long a lubricated component will last.

Studies show that approximately half of lost machine life is due to mechanical wear and approximately 80% of mechanical wear is caused by particle contamination in the oil. It therefore stands to reason that when particle contamination is reduced, wears rates go down and component service life goes up.

Recent Comments