Specifications

| OLU1A | OLU1B | |

| Nominal Flow | 2,1 l/min | 4,2 l/min |

| Standard Max. Oil Temperature¹ | 80°C | |

| Max. pressure filter housing | 20 bar | |

| Inlet connection² | 3⁄8’’ BSP female | 1⁄2’’ BSP female |

| Outlet connection | 1⁄2’’ BSP female | |

| Power supply Electric Motor | Various electrical power supplies possible (see ordering code) | |

| Suitable elements | 30HB, 30HV, 30NB, 30NV, 30G1B, 30G1V,30G3B, 30G3V, 30G6B, 30G6V, 30G12B, 30G12V 30A5V |

60HB 60HV,60NB, 60NV, 60G1B, 60G1V, 60G3B, 60G3V, 60G6B, 60G6V, 60G12B, 60G12V 60A5V |

| By-pass openings pressure | 6,2 bar (at 0 bar back pressure) | |

| Pump safety valve | 15 bar | |

| Max. tank volume | ±1.350 l | ± 2.700 l |

| Fluid compatibility³ | Hydraulic fluids according to ISO 2943 | |

| Approximate weight | 14 kg | 18 kg |

¹ For other oil temperatures, please contact Des-Case

² Inlet Connections are pump dependent. Please contact Des-Case.

³ For other fluids, please contact Des-Case

| OLU2A | OLU2B | |

| Nominal Flow | 4,2 l/min | 8,4 l/min |

| Standard Max. Oil Temperature¹ | 80°C | |

| Max. pressure filter housing | 20 bar | |

| Inlet connection² | 1⁄2’’ BSP female | 1⁄2’’ BSP female |

| Outlet connection | 1⁄2’’ BSP female | |

| Power supply Electric Motor | Various electrical power supplies possible (see ordering code) | |

| Suitable elements | 30HB, 30HV, 30NB, 30NV, 30G1B, 30G1V,30G3B, 30G3V, 30G6B, 30G6V, 30G12B, 30G12V 30A5V |

60HB 60HV, 60NB, 60NV, 60G1B, 60G1V, 60G3B, 60G3V, 60G6B, 60G6V, 60G12B, 60G12V 60A5V |

| By-pass openings pressure | 6,2 bar (at 0 bar back pressure) | |

| Pump safety valve | 15 bar | |

| Max. tank volume | ±2.700 l | ± 5.400 l |

| Fluid compatibility³ | Hydraulic fluids according to ISO 2943 | |

| Approximate weight | 21 kg | 30 kg |

¹ For other oil temperatures, please contact Des-Case

² Inlet Connections are pump dependent. Please contact Des-Case.

³ For other fluids, please contact Des-Case

| OLU4A | OLU4B | |

| Nominal Flow | 8,4 l/min | 16,3 l/min |

| Standard Max. Oil Temperature¹ | 80°C | |

| Max. pressure filter housing | 20 bar | |

| Inlet connection² | 1⁄2’’ BSP female | 3⁄4’’ BSP female |

| Outlet connection | EW 22L | |

| Power supply Electric Motor | Various electrical power supplies possible (see ordering code) | |

| Suitable elements | 30HB, 30HV, 30NB, 30NV, 30G1B, 30G1V, 30G3B, 30G3V, 30G6B, 30G6V, 30G12B, 30G12V 30A5V |

60HB 60HV, 60NB, 60NV, 60G1B, 60G1V, 60G3B, 60G3V, 60G6B, 60G6V, 60G12B, 60G12V 60A5V |

| By-pass openings pressure | 6,2 bar (at 0 bar back pressure) | |

| Pump safety valve | 15 bar | |

| Max. tank volume | ±5.400 l | ± 10.800 l |

| Fluid compatibility³ | Hydraulic fluids according to ISO 2943 | |

| Approximate weight | 39 kg | 61 kg |

¹ For other oil temperatures, please contact Des-Case

² Inlet Connections are pump dependent. Please contact Des-Case.

³ For other fluids, please contact Des-Case

| OLUW1A | OLUW1B | |

| Nominal Flow | 2,1 l/min | 4,2 l/min |

| Standard Max. Oil Temperature¹ | 80°C | |

| Max. pressure filter housing | 20 bar | |

| Inlet connection² | 3⁄8’’ BSP female | 1⁄2’’ BSP female |

| Outlet connection | 1⁄2’’ BSP female | |

| Power supply Electric Motor | Various electrical power supplies possible (see ordering code) | |

| Suitable elements | 30HB, 30HV, 30NB, 30NV, 30G1B, 30G1V, 30G3B, 30G3V, 30G6B, 30G6V, 30G12B, 30G12V 30A5V |

60HB 60HV, 60NB, 60NV, 60G1B, 60G1V, 60G3B, 60G3V, 60G6B, 60G6V, 60G12B, 60G12V 60A5V |

| Max. Water Absorption capacity | 850 ml (incl. water sorb & 30A5 element) | 1,2 l (incl. water sorb & 60a5 element) |

| By-pass openings pressure | 6,2 bar (at 0 bar back pressure) | |

| Pump safety valve | 15 bar | |

| Max. tank volume | ±1.350 l | ± 2.700 l |

| Fluid compatibility³ | Hydraulic fluids according to ISO 2943 | |

| Approximate weight | 18 kg | 22 kg |

¹ For other oil temperatures, please contact Des-Case

² Inlet Connections are pump dependent. Please contact Des-Case.

³ For other fluids, please contact Des-Case

| OLUW2A | OLUW2B | |

| Nominal Flow | 4,2 l/min | 8,4 l/min |

| Standard Max. Oil Temperature¹ | 80°C | |

| Max. pressure filter housing | 20 bar | |

| Inlet connection² | 1⁄2’’ BSP female | 1⁄2’’ BSP female |

| Outlet connection | 1⁄2’’ BSP female | |

| Power supply Electric Motor | Various electrical power supplies possible (see ordering code) | |

| Suitable elements | 30HB, 30HV, 30NB, 30NV, 30G1B, 30G1V, 30G3B, 30G3V, 30G6B, 30G6V, 30G12B, 30G12V 30A5V |

60HB 60HV, 60NB, 60NV, 60G1B, 60G1V, 60G3B, 60G3V, 60G6B, 60G6V, 60G12B, 60G12V 60A5V |

| Max. Water Absorption capacity | 1,2 l (incl. water sorb & 30A5 element) | 1,9 l (incl. water sorb & 60a5 element) |

| By-pass openings pressure | 6,2 bar (at 0 bar back pressure) | |

| Pump safety valve | 15 bar | |

| Max. tank volume | ±2.700 l | ± 5.400 l |

| Fluid compatibility³ | Hydraulic fluids according to ISO 2943 | |

| Approximate weight | 25 kg | 34 kg |

¹ For other oil temperatures, please contact Des-Case

² Inlet Connections are pump dependent. Please contact Des-Case.

³ For other fluids, please contact Des-Case

| OLUW4A | OLUW4B | |

| Nominal Flow | 8,4 l/min | 16,4 l/min |

| Standard Max. Oil Temperature¹ | 80°C | |

| Max. pressure filter housing | 20 bar | |

| Inlet connection² | 1⁄2’’ BSP female | ¾’’ BSP female |

| Outlet connection | 22 L | |

| Power supply Electric Motor | Various electrical power supplies possible (see ordering code) | |

| Suitable elements | 30HB, 30HV, 30NB, 30NV, 30G1B, 30G1V, 30G3B, 30G3V, 30A5V |

60HB 60HV, 60NB, 60NV, 60G1B, 60G1V, 60G3B, 60G3V, 60A5V |

| Max. Water Absorption capacity | 2,4 l (incl. water sorb & 30A5 element) | 3,8 l (incl. water sorb & 60a5 element) |

| By-pass openings pressure | 6,2 bar (at 0 bar back pressure) | |

| Pump safety valve | 15 bar | |

| Max. tank volume | ±5.400 l | ± 10.800 l |

| Fluid compatibility³ | Hydraulic fluids according to ISO 2943 | |

| Approximate weight | 43 kg | 65 kg |

¹ For other oil temperatures, please contact Des-Case

² Inlet Connections are pump dependent. Please contact Des-Case.

³ For other fluids, please contact Des-Case

| OLUH1A | OLUH1B | OLUH1B | |

| Nominal Flow | Approx. 2,9 l/min with 2 kW heater Contact Des-Case for 4kW heater and flows exceeding 2,9 l/min |

||

| Standard Max. Oil Temperature¹ | 80°C | ||

| Max. pressure filter housing | 20 bar | ||

| Inlet connection² | 3⁄8’’ BSP female | 1⁄2’’ BSP female | |

| Outlet connection | 1⁄2’’ BSP female | ||

| Heater Capacity | 2 kW | 2 kW | 4 kW |

| Power supply Electric Motor | Various electrical power supplies possible (see ordering code) | ||

| Suitable elements | 30HB, 30HV, 30NB, 30NV, 30G1B, 30G1V,30G3B, 30G3V, 30G6B, 30G6V, 30G12B, 30G12V 30A5V |

60HB 60HV,60NB, 60NV, 60G1B, 60G1V, 60G3B, 60G3V, 60G6B, 60G6V, 60G12B, 60G12V 60A5V |

|

| By-pass openings pressure | 6,2 bar (at 0 bar back pressure) | ||

| Pump safety valve | 15 bar | ||

| Max. tank volume | ±1.350 l | ± 2.700 l | |

| Fluid compatibility³ | Hydraulic fluids according to ISO 2943 | ||

| Approximate weight | 24 kg | 28 kg | 30 kg |

¹ For other oil temperatures, please contact Des-Case

² Inlet Connections are pump dependent. Please contact Des-Case.

³ For other fluids, please contact Des-Case

Features

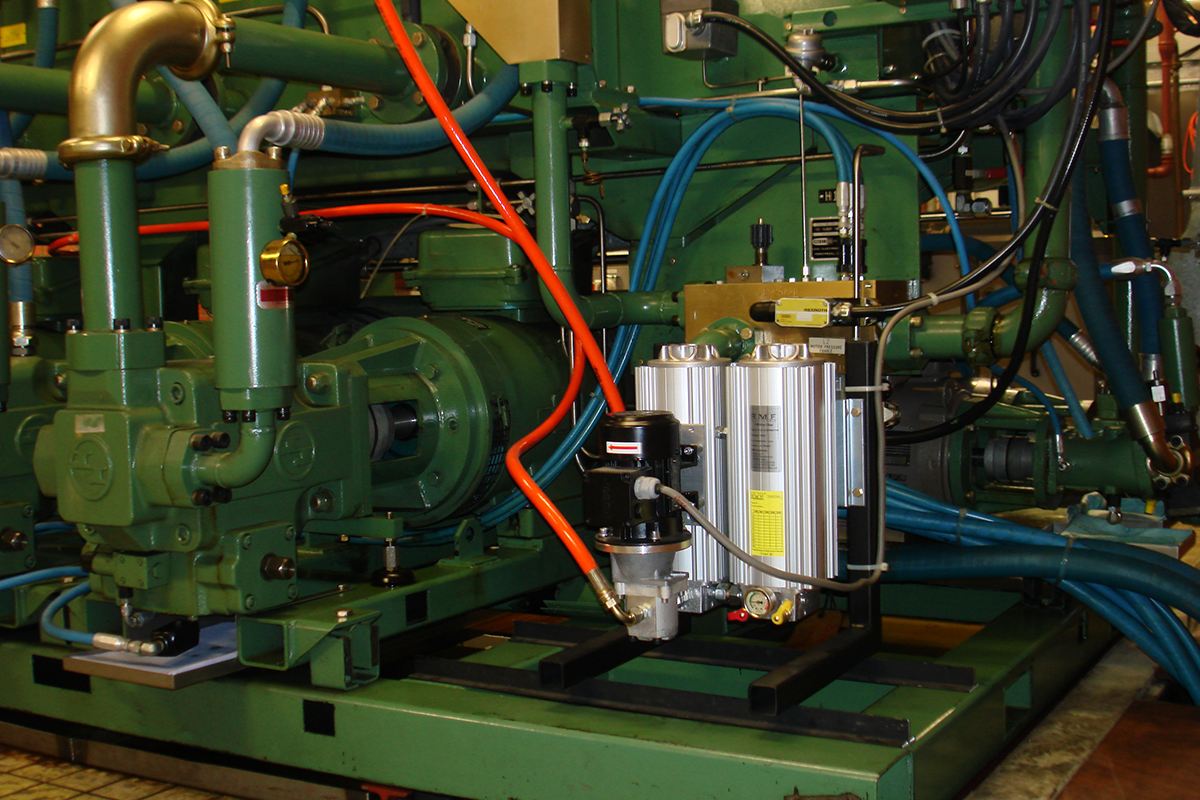

Performance

The principle of the RMF Systems filters is based on the unique original filter elements. With a choice of filter fineness down to 0,5 micron and Filter efficiency up to β4=10.000, they have the capacity to remove even the smallest of dirt particles from the oil. RMF System’s Off-line kidney loop oil filtration system offers a wide range of elements in micron sizes, filter media, and fluid compatibility. Combi-elements (water and solid particle retention) complement the unique range.

Water Absorbing

RMF Water absorbing filters are off-line filters that use a special water-absorbing spin-on as a pre-filter. The fluid is pumped through the pre-filter which removes most water and larger solid contamination, in the second stage the fluid passes through the RMF cellulose micro filter where final water removal takes place as well as solid particle removal.

Heated Off-Line Filters

The ‘Heated unit’ is a unique progression of the Off-line filter series. The filtration of high viscosity oils, in both hydraulic and lubrication systems, is an almost impossible task for fine filters as the thickness of these oils ‘block’ almost all normal filters. The RMF Heated unit warms the oil in a specific manner, allowing the viscosity to be reduced to a level which will permit fine filtration without the oil being exposed to too high temperatures that could cause overheating and burning of the oil, rendering it useless.

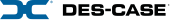

Applications

The RMF off-line units attack contamination of your system at the source. In addition to solid particles, these filters are also capable of removing water from the oil. The use of RMF filters means less defects, less maintenance and less wear and tear of the hydraulic components. The RMF Off-Line units can be fitted to every imaginable industrial application where hydraulic or lubrication systems are present.

In recent years RMF Systems have developed a great deal of experience in cleaning and keeping clean hydraulic and lubrication systems in the:

- Steel industry

- Plastic moulding industry

- Maritime industry

- Petro-chemical industry

- Paper industry

Efficiency

The hydraulic market accepts that 80% of mechanical failures are caused by contamination in the system. The RMF Off-Line Units attack contamination of your systems at source. In addition to solid particles, these filters are also capable of removing water from the oil. The use of RMF filters means less defects, less maintenance, and less wear and tear of the hydraulic components. The RMF Off-Line Units can be fitted to every imaginable industrial application where hydraulic or lubrication systems are present.

Benefits

- Reduced cost of ownership

- Extremely clean oil due to high filtration efficiency

- Prevention of channel forming by radial filtration direction

- Large dirt holding capacity

- Large water holding capacity

- Compact and easy maintenance design

- Longer usage life for oil and components

Recent Comments