Specifications

| BPU1A | BPU1B | |

| Nominal Flow | 2,1 l/min | 4,2 l/min |

| Standard Max. Oil Temperature¹ | 80°C | |

| Max. pressure filter housing | 20 bar | |

| Inlet connection | 1⁄4’’ BSP female | |

| Outlet connection | 1⁄2’’ BSP female | |

| Operating pressure flow control valve (min – max) | 12 – 420 bar | |

| Suitable elements | 30HB, 30HV, 30NB, 30NV, 30G1B, 30G1V,30G3B, 30G3V, 30G6B, 30G6V, 30G12B, 30G12V 30A5V |

60HB, 60HV, 60NB, 60NV, 60G1B, 60G1V, 60G3B, 60G3V, 60G6B, 60G6V, 60G12B, 60G12V 60A5V |

| By-pass openings pressure | 6,2 bar (at 0 bar back pressure) | |

| Max. tank volume | ± 750 l | ± 1500 l |

| Fluid compatibility² | Hydraulic fluids according to ISO 2943 | |

| Approximate weight | 6 kg | 10 kg |

¹ For other oil temperatures, please contact Des-Case

² For other fluids, please contact Des-Case

| BPU2A | BPU2B | |

| Nominal Flow | 4,2 l/min | 8,4 l/min |

| Standard Max. Oil Temperature¹ | 80°C | |

| Max. pressure filter housing | 20 bar | |

| Inlet connection | 1⁄4’’ BSP female | |

| Outlet connection | 1⁄2’’ BSP female | |

| Operating pressure flow control valve (min – max) | 12 – 420 bar | |

| Suitable elements | 30HB, 30HV, 30NB, 30NV, 30G1B, 30G1V,30G3B, 30G3V, 30G6B, 30G6V, 30G12B, 30G12V 30A5V |

60HB, 60HV, 60NB, 60NV, 60G1B, 60G1V, 60G3B, 60G3V, 60G6B, 60G6V, 60G12B, 60G12V 60A5V |

| By-pass openings pressure | 6,2 bar (at 0 bar back pressure) | |

| Max. tank volume | ± 1.500 l | ± 3.000 l |

| Fluid compatibility² | Hydraulic fluids according to ISO 2943 | |

| Approximate weight | 13 kg | 18 kg |

¹ For other oil temperatures, please contact Des-Case

² For other fluids, please contact Des-Case

| BPUW1A | BPUW1B | |

| Nominal Flow | 2,1 l/min | 4,2 l/min |

| Standard Max. Oil Temperature¹ | 80°C | |

| Max. pressure filter housing | 20 bar | |

| Inlet connection | 1⁄4’’ BSP female | |

| Outlet connection | 1⁄2’’ BSP female | |

| Operating pressure flow control valve (min – max) | 12 – 420 bar | |

| Suitable elements | 30HB, 30HV, 30NB, 30NV, 30G1B, 30G1V,30G3B, 30G3V, 30G6B, 30G6V, 30G12B, 30G12V 30A5V |

60HB, 60HV, 60NB, 60NV, 60G1B, 60G1V, 60G3B, 60G3V, 60G6B, 60G6V, 60G12B, 60G12V 60A5V |

| Max. Water Absorption capacity | 850 ml (incl. water sorb & 30A5 element) | 1,2 l (incl. water sorb & 60a5 element) |

| By-pass openings pressure | 6,2 bar (at 0 bar back pressure) | |

| Max. tank volume | ± 750 l | ± 1500 l |

| Fluid compatibility² | Hydraulic fluids according to ISO 2943 | |

| Approximate weight | 6 kg | 10 kg |

¹ For other oil temperatures, please contact Des-Case

² For other fluids, please contact Des-Case

| BPUW2A | |

| Nominal Flow | 4,2 l/min |

| Standard Max. Oil Temperature¹ | 80°C |

| Max. pressure filter housing | 20 bar |

| Inlet connection | 1⁄4’’ BSP female |

| Outlet connection | 1⁄2’’ BSP female |

| Operating pressure flow control valve (min – max) | 12 – 420 bar |

| Suitable elements | 30HB, 30HV, 30NB, 30NV, 30G1B, 30G1V,30G3B, 30G3V, 30G6B, 30G6V, 30G12B, 30G12V 30A5V |

| Max. Water Absorption capacity | 1,2 l (incl. water sorb & 30A5 element) |

| By-pass openings pressure | 6,2 bar (at 0 bar back pressure) |

| Max. tank volume | ± 1500 l |

| Fluid compatibility² | Hydraulic fluids according to ISO 2943 |

| Approximate weight | 17 kg |

¹ For other oil temperatures, please contact Des-Case

² For other fluids, please contact Des-Case

Features

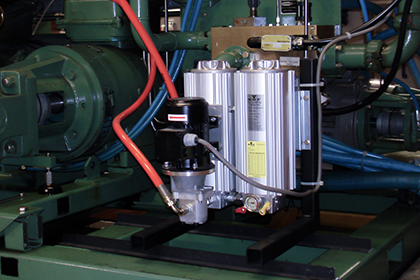

The Bypass filter comes equipped with an integrated pressure compensated flow control valve. This valve bleeds oil from the main hydraulic system, passes this through the filter after which it is returned to the hydraulic reservoir. The amount of oil extracted from the main system at any time is insignificant ensuring that it will not affect the working of the main system. Most commonly used biodegradable oils in the mobile sector are suitable for filtration with RMF filter elements.

RMF Bypass filter units can be fitted to every imaginable mobile application where hydraulic and/or transmission systems are present. Installation is very simple, the filter housing provides mounting slots on all four sides and the pressure and return connections are available on the side and the back of the Bypass unit. In recent years RMF Systems have developed a great deal of experience in cleaning and keeping clean hydraulic and transmission systems on:

- excavators

- wheel loaders

- forestry machines

- asphalt machines

- concrete pumps

- aviation ground support equipment

- agricultural machines

- Extremely clean oil due to high filtration efficiency

- Prevention of channel forming by radial filtration direction

- Large dirt and water holding capacity

- Compact and easy-maintenance design

- Environmentally friendly elements available

- Longer usage life for oil and components

- Reduces cost of ownership

Recent Comments