Storage & Handling Case Study

The Journey to World-Class Storage & Handling – Basic American Foods

CustomerBasic American Foods |

IndustryFood & Beverage |

Company Profile

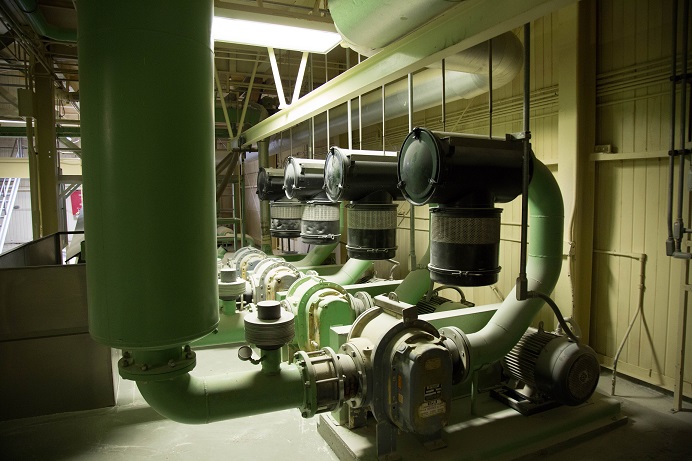

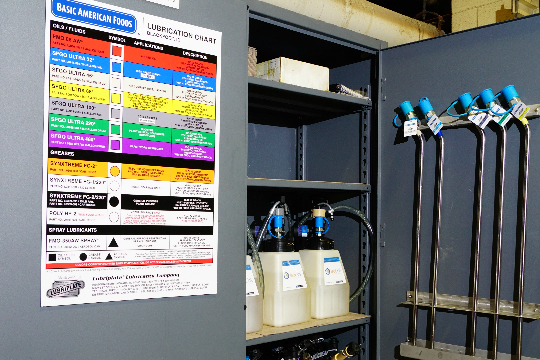

Basic American Foods operates five facilities throughout Idaho, California and Washington. To serve their customer-base of restaurants, schools, grocery and club stores, hospitals and families around the country, Basic American Foods adheres to their values of integrity and taste to remain the market leader in dried potato and bean products. This family-owned business processes over two million potatoes each day in their Blackfoot, Idaho facility where Des-Case collaborated with Basic American Foods to create a premier lube room and seal and protect eight critical assets.

The dollars add up when you replace a $10,000 pump every year, and we have pumps everywhere.

The Challenge

When Scott Fischer, Maintenance Manager, joined Basic American Foods, he recognized that the Blackfoot Basic American Foods plant was in need of a dedicated lubricant storage and handling process and products to support his reliability program goals. At a high level, the 70-year-old facility was losing money with monthly shutdowns and annual equipment rebuilds. His goal? “To make it all last longer, and reduce overall costs.”

Getting Leadership Buy-In

What did Basic American Foods leadership want to know before approving a lubrication program overhaul? What the investment is worth. Because reliability initiatives and programs often take months or years to prove results, they often fail or become forgotten. Utilizing metrics and case studies from comparable programs, Fisher and his colleague, Corinne Jeffs, Reliability Manager, presented reliability case studies from companies with proven ROI from their investment. “The dollars add up when you replace a $10,000 pump every year, and we have pumps everywhere.” In addition to general maintenance costs and annual replacement, Fisher explained that if a pump fails during the night, Basic American Foods was faced with significant downtime and major dollars lost. To make their pitch, Fisher and Jeffs went on a tour from executive to executive in order to prove they had the evidence to back up their request for funding and support.

Recent Comments