RS Breather Case Study

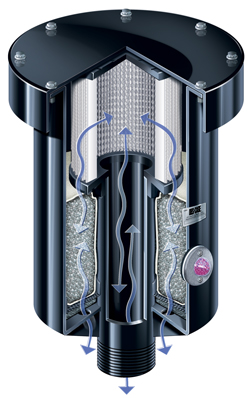

Rebuildable Steel Breather (DC-RS-50) TECASEN

CustomerRetail Manufacturer-Industrial Equipment |

IndustryContamination Control |

Company Profile

For years, TECASEN has been an innovative driver, providing their customers with industrial solutions that eliminate money spent due to the contamination of oils and fuels. TECASEN solutions protect industrial equipment by eliminating particulate and moisture contamination ultimately resulting in equipment longevity and a reduction in operation downtime.

Website

Products Used

The Des-Case solution was intuitively engineered and the serviceability was best in class when compared to other options.

The Challenge

When critical and costly lubricants are stored, it is imperative that the levels of contamination are reduced from the storage tanks that house these lubricants.

Contamination is the leading cause of machinery failure by directly impairing the lubricant’s ability to control friction, wear, and corrosion. Particle count and moisture level are two vital factors within the lubricants that can lead to equipment malfunction.

Fearing that the contamination within the oil would result in detrimental consequences, TECASEN’s customer asked them to find a solution that could protect a series of 10,000 gallon bulk oil storage tanks. Knowing that these tanks supplied costly industrial equipment, TECASEN looked to Des-Case to provide a solution for the bulk storage applications.

Recent Comments